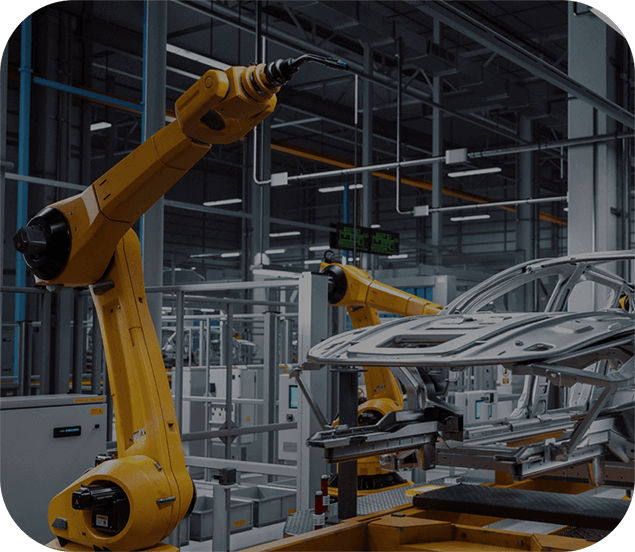

How AR is changing the manufacturing landscape

Discover how the integration of AR into your manufacturing environment can streamline operations, reduce errors, and pave the way for a more sustainable, agile, and forward-thinking approach to production.

Accelerate product development with AR collaboration

Product development and prototyping is a crucial stage requiring time and effort for the best outcome. With AR collaboration, designers and engineers can provide unique insights, work hand-in-hand virtually using AR tools, and come up with a working prototype in less time.

Inspect assembly lines and safety standards in real time

Mechanized manufacturing processes need regular inspections to ensure safety and maintain efficiency. Supervisors can use AR Iive streaming to see and identify assembly line issues and provide real-time instructions to their crews.

Conduct live training sessions from anywhere

AR technology ensures safer training environments and reduces the learning curve for employees. Manufacturers can organize live training sessions where new personnel can join from any AR-supported device and learn how to operate expensive machinery.

Work hands-free with smart-glass support

Maintenance down times significantly impact the throughput and production schedules, which can lead to incurred losses. Technicians can speed up maintenance procedures with efficiency using AR smart glasses. They can receive visual instructions on their smart glass while skipping the tedious process of going through a manual.

Benefits of augmented reality in the manufacturing industry

Using AR in manufacturing, organizations benefit from the following:

Enhanced worker efficiency leading to increased productivity

Reduced errors and rework in all stages of manufacturing

Faster troubleshooting and problem-solving

Safer training environments

How augmented reality solutions work in manufacturing industry

Connect with your team

Engineers can start or schedule a remote session with the crew from any device. They can send an invite through SMS or email, or send the join link directly.

See what your frontline sees

Once the frontline crew joins the session, you can access their camera to view the assembly or maintenance process live.

Collaborate using AR tools

Engineers can interact with the crew using text, voice chat, and AR annotations to analyze issues in details and facilitate faster problem solving.

Optimize production workflows with these key features

Sign up now and experience AR in manufacturing for free!

Frequently Asked Questions

What is augmented reality in manufacturing?

Augmented reality in manufacturing is a technology that overlays digital content, such as a 3D object, text, or images onto the physical world in real time. It can be used on supported devices like smart glasses, smart phones, and tablets. With the combination of hardware and software, operators and technicians can get a real-time view of machinery work, provide visual instructions, and collaborate with AR tools.

How is augmented reality used in manufacturing?

Based on the functionality built into the tool, augmented reality can be used for various purposes in manufacturing. Manufacturers can use industrial augmented reality for interactive live training, remote operations management, remote maintenance, and live collaborations in prototyping and assembly.

Why is augmented reality important in manufacturing?

One of the main reasons why manufacturers are adopting AR in significant numbers is that it aligns with the principles of Industry 4.0 (aka the Fourth Industrial Revolution) and the smart factory concept. AR software like Zoho Lens requires minimal setup, and it fits seamlessly into your digital infrastructure, creating interconnected and highly efficient production environments.

Is augmented reality suitable for small and medium-sized manufacturing businesses?

Yes, AR is increasingly accessible to businesses of all sizes. Zoho Lens offers scalability with affordable pricing plans, and it can be deployed on commonly available devices like smartphones and tablets, making it feasible and cost-effective for SMEs to adopt AR technology.

What is the application of VR and AR in manufacturing?

The applications of virtual reality (VR) and AR are quite similar, with the only difference being the level of interaction with the real world. With VR, users are cut off from the physical world and can view and interact with computer-generated simulations of automobile designs, shop-floor equipment, and working environments.

While VR is great for product visualizations and immersive training sessions, AR is preferred for shop-floor operations and live maintenance, or collaborative works due to its real-world integration.

What are the minimum requirements for implementing augmented reality in manufacturing processes?

To use augmented reality on a daily basis, you’ll need:

- Hardware: Devices that support AR technology like smart glasses, tablets, or smartphones.

- Software: AR software platforms or applications for content creation, visualization, and interaction.

- Connectivity: Reliable internet or network access, especially for remote assistance.

- Content: 3D models, digital instructions, and other relevant content for overlaying onto the physical environment. (These tools will usually be built into AR software like Zoho Lens.)