Common challenges facing the manufacturing industry

Quality has left the chat

Consistency in quality is fundamental to any manufacturing firm. But this is easier said than done. Poorly managed workflows, a lack of automation, inaccurate demand forecasts, and the absence of risk management can set off a domino effect, leading to dissatisfied customers and, ultimately, tainted brand reputation.

Cybersecurity in jeopardy

While you use digital tools to create products your customers love, you also run the risk of being exposed to cybersecurity threats that can cost your highly sensitive data and manufacturing processes dearly, placing product quality and data integrity in peril.

Today's weather: Unknown demand forecast

Sometimes, erroneous demand forecast calculations can leave your project hanging by a thread, significantly impacting inventory, throughput, and financial planning. Consequentially, revenue suffers, and customers are left discontented.

Supply chains fail to deliver

The steady functioning of a supply chain warrants efficient inventory management, a robust risk management plan, minimal wastage, and end-to-end visibility. While a lean lean Six-Sigma approach can certainly help, unprecedented environmental and geopolitical friction can often be devastating, giving rise to unforeseen losses, decreased efficiency, and low-grade deliverables.

Industry-specific solutions

Process manufacturing industries

Distinct raw materials are combined here and undergo repetitive processes to manufacture identical finished products. Food, chemical, and pharmaceutical industries can all benefit from project management, which helps with constant supervision and automation of workflows.

Discrete manufacturing industries

Distinct, identifiable end products are created here—automobiles, construction materials, toys, furniture, clothes and more. Project management can help with setting cost-cutting measures and quality standards, as well as establishing proper inventory control.

What manufacturing industries need

Lean manufacturing

Reduced wastage and enhanced efficiency help roll out end products of unparalleled quality.

Efficient management

Periodic inventory checks, close monitoring of workflows, budget control, and continual improvement processes minimize product defects and inconsistencies.

Data analytics

To stay ahead of the game and keep customers satisfied, investing in software that analyzes current data, predicts future trends, and spots bottlenecks along the way is essential.

Automated workflows

Introducing automation to manufacturing operations reduces human error, latency, and lead time, ensuring only high-grade products make it to the conveyor belt.

Rigid security measures

Potential security lapses can be prevented and sensitive data can be safeguarded by conducting regular training sessions and implementing security policies.

Build your projects, your way

Custom Modules

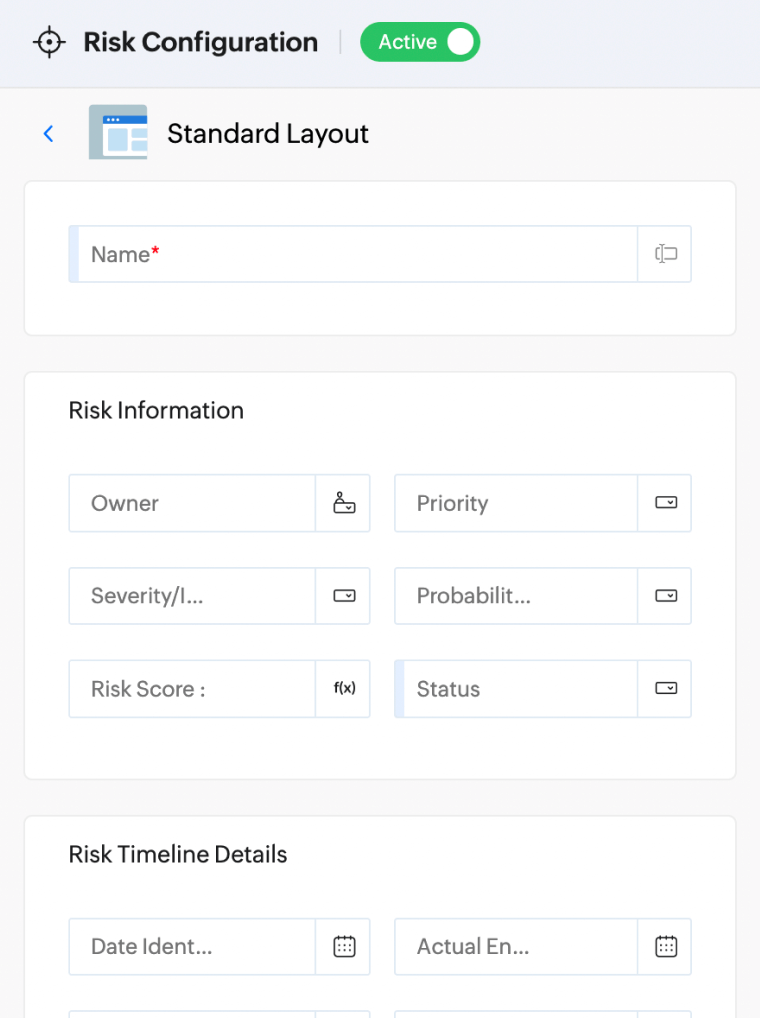

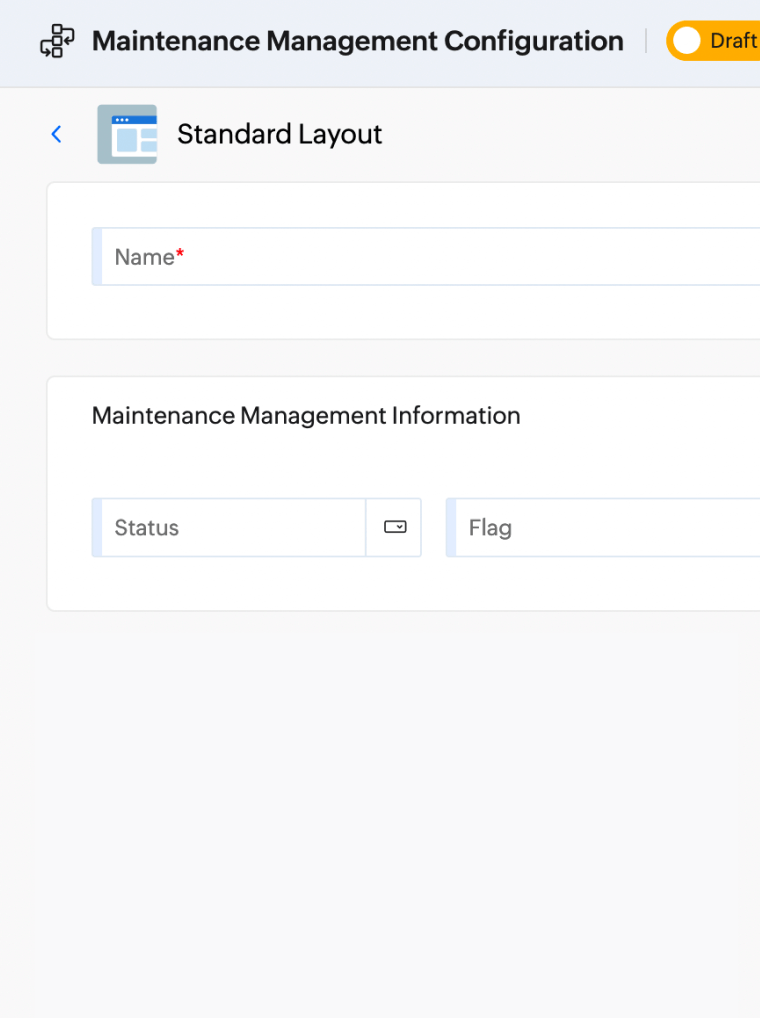

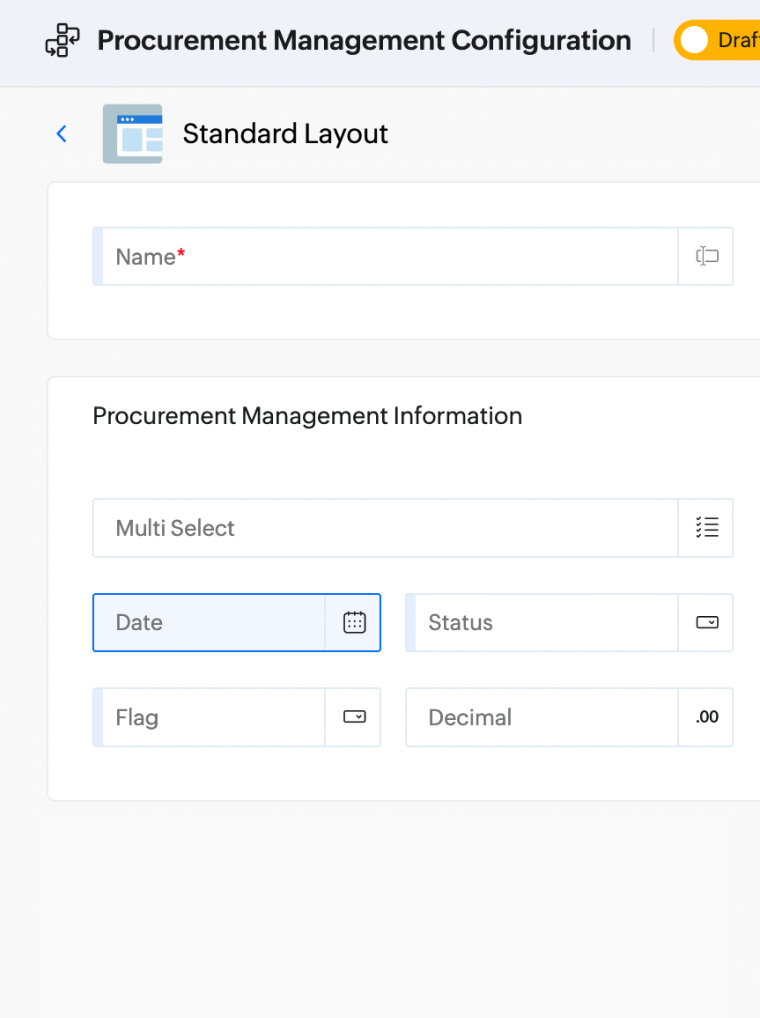

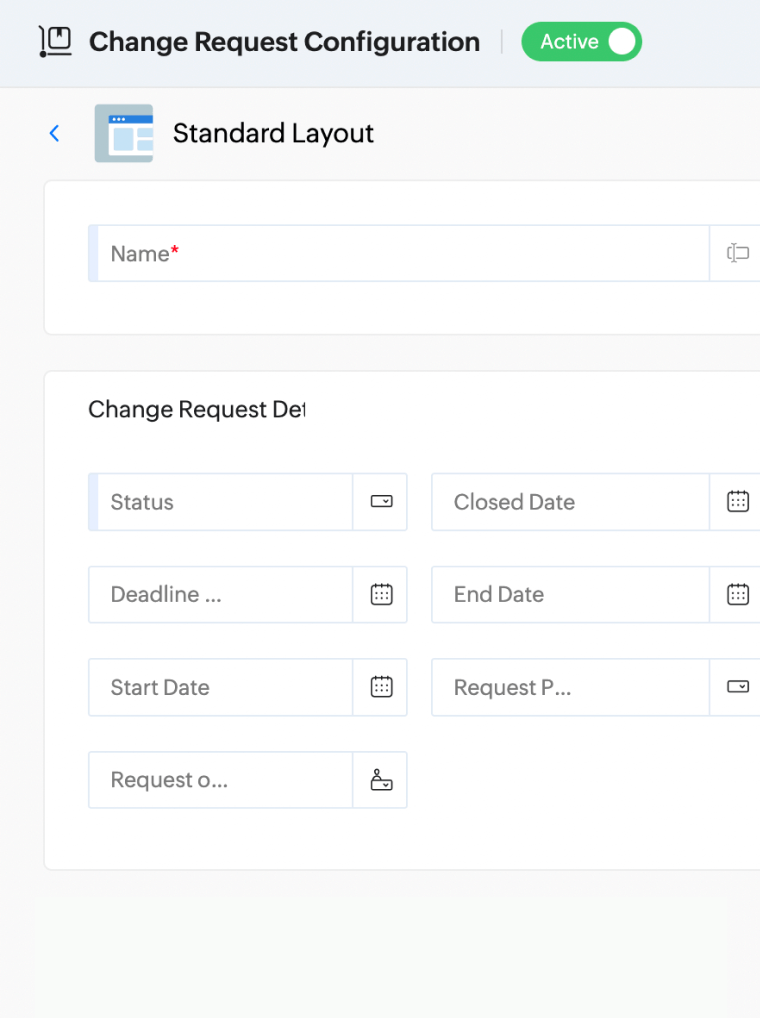

Bring your manufacturing operations into custom modules and run your projects with the same precision, real-time visibility, and control like you would on your shop floor.

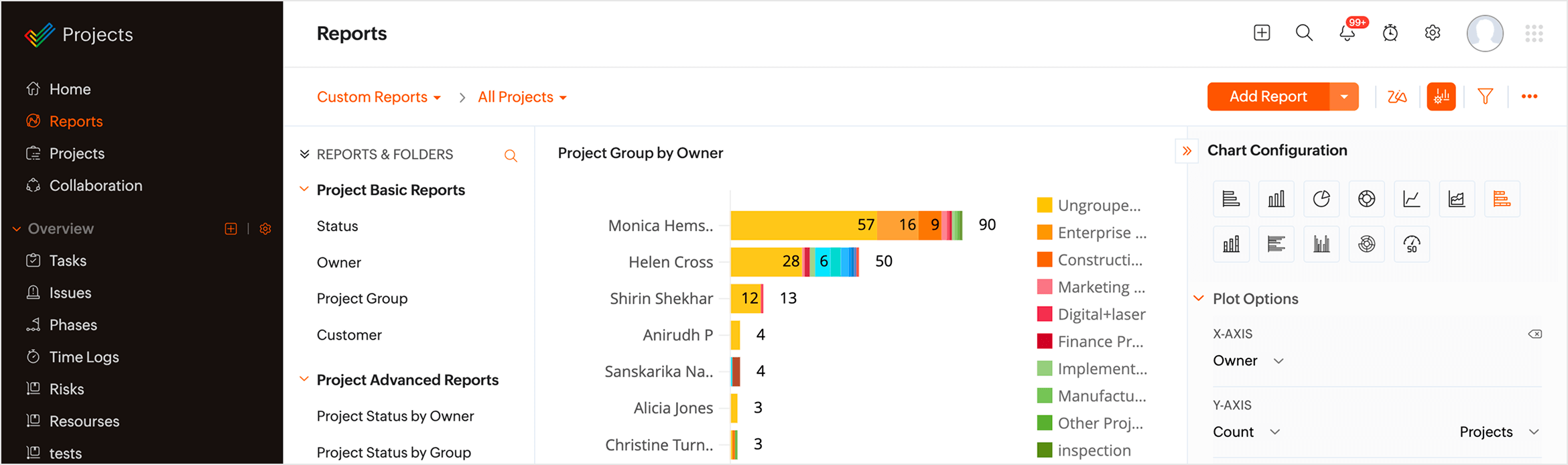

Custom Reports

Capture critical insights into different phases of your manufacturing projects—right from design to delivery, all while adhering to your objectives.

Custom Dashboards

Model your dashboards to reflect defect patterns, stock levels, or workforce performance through charts, graphs or bars.

Drill down into data

- Gather real-time end-to-end updates on custom modules that can be personalized to accommodate your unique quality metrics.

- Gain actionable Zia insights into your performance with our intuitive Custom Reports and Dashboards.

- Increase visibility into progress, reduce downtime, and carry out risk mitigation in real-time.

Customize your manufacturing projects

Turning raw materials into unique, real products of value warrants more than just your rudimentary project management software. That's why we introduced custom modules, so you can customize your journey to plan, track, and manufacture quality deliverables.

How Zoho Projects gets you there

Intelligence for the Modern Team

With Model Context Protocol (MCP), you can analyze all your project data and surface insights in seconds, right from one, unified window.

Model Context Protocol

Model Context Protocol (MCP) now lets you integrate Zoho Projects, along with several other Zoho products, directly with your preferred Generative AI model. Query project data, pull task histories, and generate insights without switching windows.

- Predict machine slow down at specific loads

- Detect non-compliance patterns

- Compare predicted versus actual capacity usage

- Analyze historical project data

- Seamlessly integrate with third-party tools

Agentic AI COMING SOON

Agentic AI takes this further by enabling Zia to act autonomously on your behalf. You define the rules and let the agent handle the mindless, repetitive work.

- Predict material shortage

- Auto-generate weekly progress reports

- Recommend optimized workforce planning

Handy integrations

Here are a few integrations that further increase Zoho Projects capabilities and functionality. That’s not all. Connect with other applications or easily build your own extensions with our Marketplace.

Explore NowFrequently Asked Questions

Manufacturing project management software is designed to help manufacturers plan, organize, and execute production projects, from design to delivery. It prioritizes tasks, distributes resources, plans production schedules, and centralizes manufacturing documentation to improve project visibility, enable cross-team coordination, and ensure on-time delivery.

Zoho Projects helps automate manufacturing processes through features like workflow automation that manages recurring tasks and production milestones and blueprints that automate approvals. The Gantt chart, Kanban, Project Timeline, and the Collaboration module improve shop floor and office collaboration and streamline production planning processes.

Yes, absolutely! Zoho Projects improves on-time delivery through real-time project tracking, dependency management, and automated alerts. With the Gantt chart, Status Timeline, and Kanban, teams can spot production bottlenecks, reduce manufacturing delays, and set practical delivery timelines.

You can readily integrate Zoho Projects with ERP systems, manufacturing accounting software, CRM software, and document management tools. With these manufacturing software integrations, you can manage project execution, procurement, finance, and inventory workflows from one place.

Zoho Projects facilitates manufacturing quality control by tracking inspections, automating approvals, implementing quality checks, and taking corrective actions right within your projects. With Zoho Projects' in-built audit trails, centralized documentation, and granular access control, you always keep your manufacturing projects compliant.

Zoho Projects' reporting and analytics features provide data-driven project reports, custom dashboards, and workload charts that can track progress, milestone adherence, resource utilization, and production delays, helping improve manufacturing efficiency and project performance.

Zoho Projects can be implemented by using pre-defined manufacturing project templates that you can use to create projects in just a few seconds. With its fast onboarding, minimal setup, and intuitive project management interface, Zoho Projects helps you streamline production operations, setup workflows, and deliver manufacturing projects on time.

Using task management software for managing manufacturing projects can help increase productivity, meet pre-defined standards, and keep errors to a minimum. Listed below are some top task management tools that you can use for manufacturing sectors.

- Task Management System for Construction Material Manufacturing Industry: Specialized software that helps manage supply chains, track construction material orders, and ensure on-time delivery of materials.

- Project Management Software for Food Industry: Software that provides real-time tracking of production schedules, ingredient sourcing, packaging, and distribution.

- Task Management Software for Furniture Manufacturing Industry: Streamlines production processes by tracking assembly line tasks, material sourcing, and shipment schedules.

- Task Management Software for Pharmaceutical Manufacturing Industry: Tracks manufacturing schedules, regulatory compliance tasks, and quality assurance checks.

- Task Management Software for Engineering Goods Manufacturing Industry: Coordinates design, prototyping, production, and testing phases while tracking material usage, labor resources, and product quality.

- Task Management Tool for Chemical Manufacturing Industry: Helps track chemical production batches, manage safety protocols, and monitor environmental impact.

- Task Management App for Electronics Manufacturing Industry: Supports tracking of component assembly, quality testing, and shipping.

- Task Management Software for Rubber Manufacturing Industry: Helps streamline the rubber production process by optimizing raw material management.

- Task Management Tool for Garment Manufacturing Industry: Tracks production stages from design to assembly, manages supply chain logistics.

- Task Management Software for Automobile Manufacturing Industry: Manages vehicle production lines, part manufacturing schedules, and assembly tasks.

- Task Management Software for Machinery Manufacturing Industry: Tracks the production of machinery parts, equipment assembly, and final testing specifications.

- Task Management Software for Footwear Manufacturing Industry: Coordinates design, production, and shipment of footwear.

- Task Management App for Equipment Manufacturing Industry: Tracks equipment production, assembly line tasks, testing, and shipment.

- Task Management Software for Paper Manufacturing Industry: Manages production schedules, inventory, and raw material sourcing.